Description

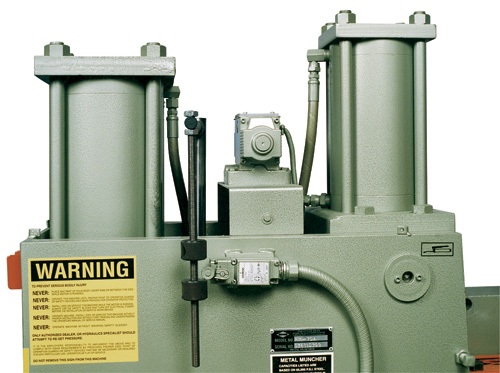

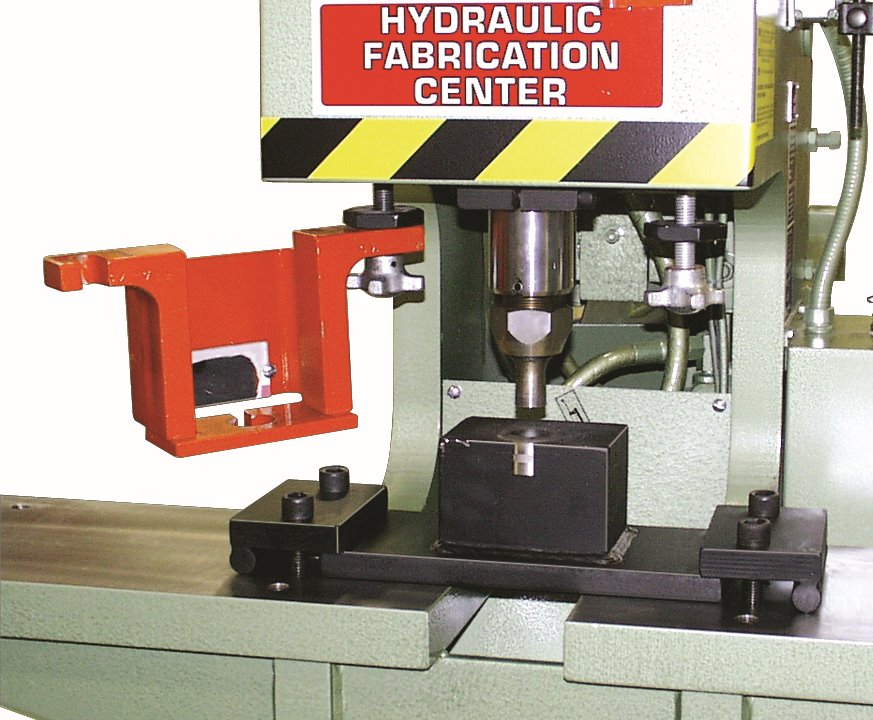

Two-Cylinder / Two Person Operation

The punch and shear end may be operated separately, independently, and simultaneously at full capacity and full speed.

The MM-Series Fabrication Center includes:

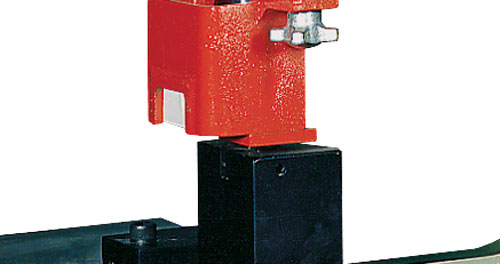

- Punch Press

- Flat Bar/Plate Shear

- Coper

- Notcher

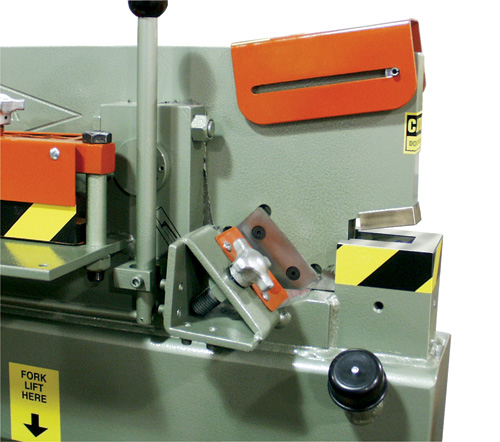

- Angle Shear

- Optional Round and Square Shear

Kalamazoo Metal Muncher Features

- Adjustable stroke length up to 9″

- Up to 3″ ram size . . . Easily adapts to accept over-size / special tooling

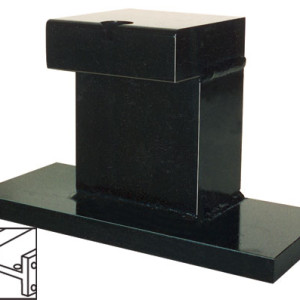

- Easy to change punch and die holder. Die block easily removed to accept unlimited accessories

- Swing-away stripper gives ready access to the ram stem and makes punch changing quick and easy

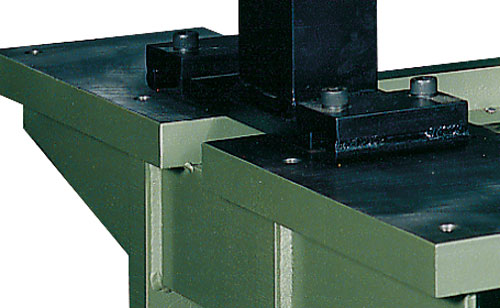

- Standard large table gives the user an ideal work area and accepts up to a 48″ breakset and large special tooling

- All workstations are approximately the same height, for ease in material handling

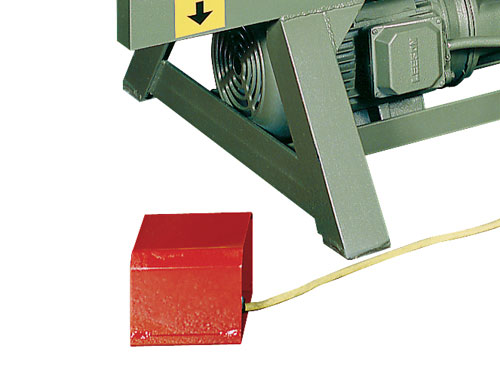

- Press cylinder is foot pedal activated (Rear electric foot control for shear end available)

- Includes complete electrics . . . 220/440v. standard. Other voltages available at additional cost by request.

- Comes complete with hydraulic oil; ready to operate. Lubrication points are marked and easily accessible.

Special Capacity Optional Feature

- Hy-performance blade to increase flat bar shearing capacity

- Speed-up kit increases ram speed on press and shear end cylinder

- Adjustable tonnage control feature available

Features differ on 40-ton models.